How are nonwovens made?

The production of nonwovens takes place in three stages, although modern technology allows an overlapping of some stages, and in some cases all three stages can take place at the same time.

The three stages are:

- Calendering

- Air through

- Needle punching

- Hydro-entanglement

- Stichbonding

- Mechanical treatment

- Surface modification

- Coating

Web formation

Nonwovens manufacturing starts by the arrangement of fibres in a sheet or web. The fibres can be staple fibres or filaments extruded from molten polymer granules.

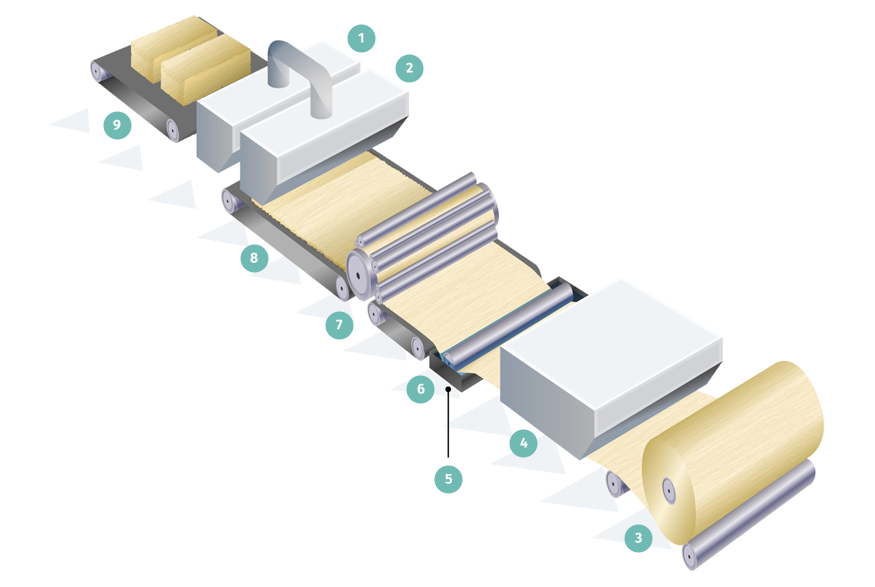

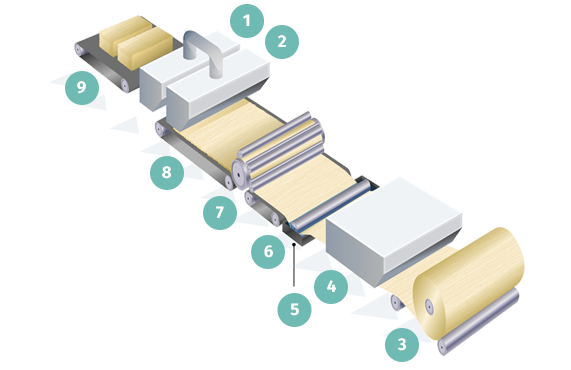

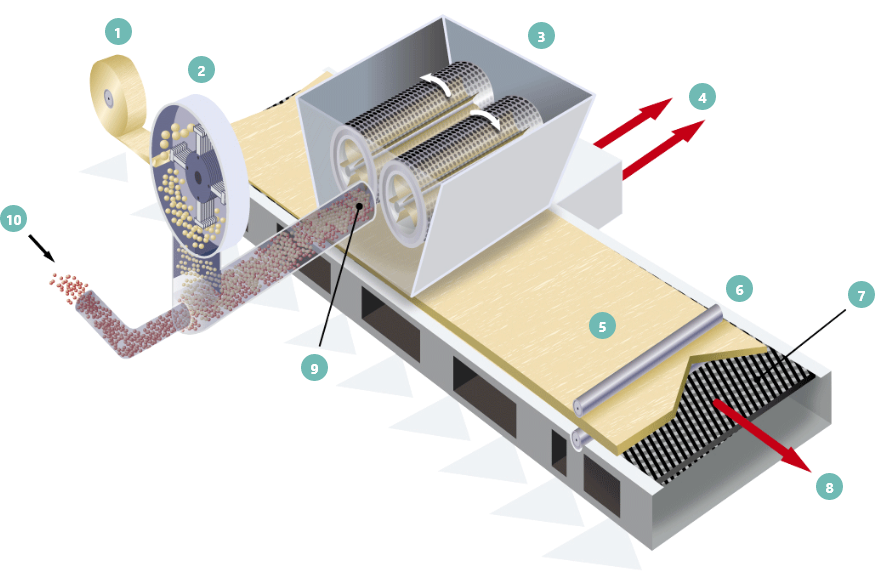

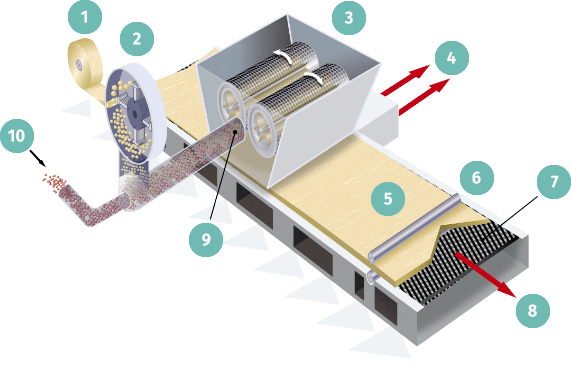

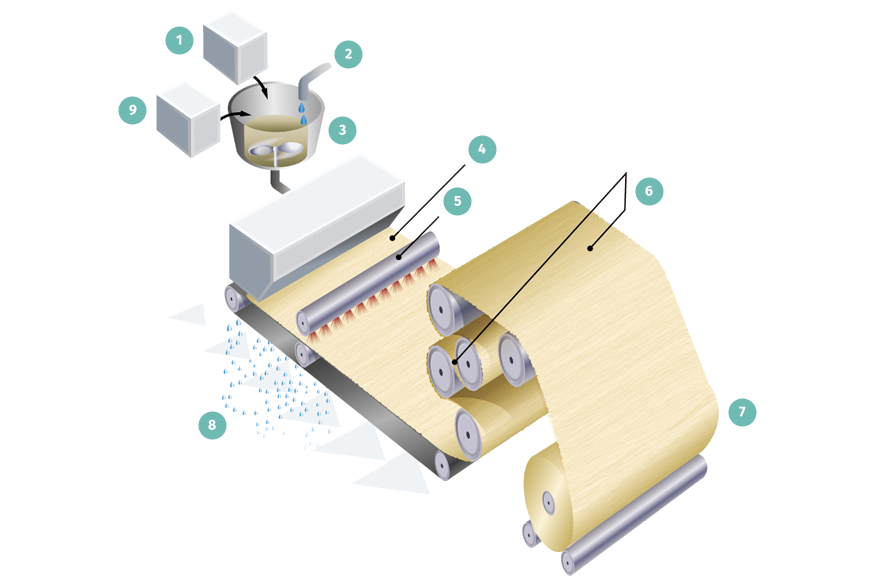

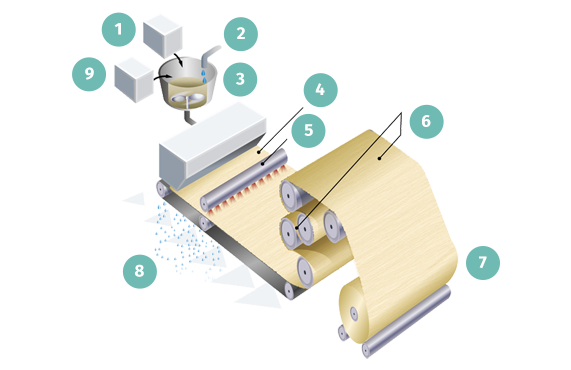

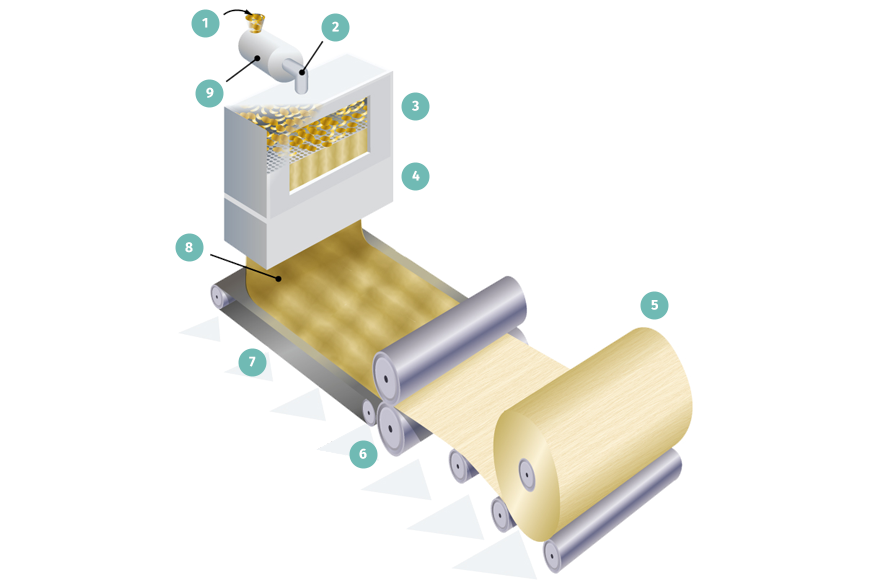

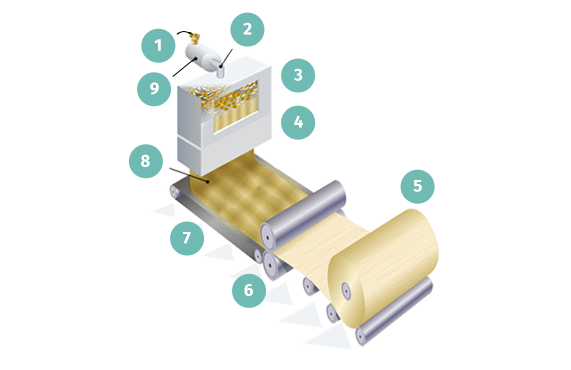

Illustrations of some of the methods used to form a web:

- Drylaid-carded

- Short Fiber Airlaid

- Wetlaid

- Spunlaid

- Meltblown

- Submicron spinning

- Bale opener

- Chute feed

- Wind up

- Drying

- Pan with liquid binder

- Binder impregnation

- Card

- Staple fibre from bale opener or blender

- Bales of staple fibre

- Short fibre feed

- Hammer mill (defibrator)

- Forming head

- Air out

- Web

- Compactor

- Moving wire mesh

- To further bonding

- Fibres + air in

- Thermofusible fibres

- Long fibre

- Water

- Fibre and water (slurry)

- Webforming

- Binder impregnation

- Drying

- Windup

- Excess water removal

- Wood pulp

The strength of the random oriented web is rather similar in all directions in the plane of the fabric. A wide range of natural, mineral, synthetic and man-made fibres of varying lengths can be used.

- Polymer chips feed

- Liquid polymer

- Extrusion die

- Filament attenuator (cooling and stretching)

- Wind up

- Calender bonding

- Laydown

- Fiber dispersion

- Extruder

Polymer granules are extruded into filaments through so called spinnerets. The continuous filaments are stretched and quenched before being deposited on conveyor belt to form a uniform web. The spunlaid process results into nonwovens with an increased strength compared to carding, due to the attenuation of the filaments. The downside is that the choice of raw materials is more restricted. Co-extrusion of two components leads to bico fibres, either adding more properties to the web or allowing air-through bonding. Please note that the word spunbonded is reserved for thermo bonded spunlaid.

Technologies in the market are sub-micron meltblown, centrifugal spinning, solution spinning and electrospinning. Although the productivity of these methods is low compared to spunmelt, they are increasingly important for the unique properties they can add to a nonwoven.

Web bonding

Webs have a limited initial strength right after the web formation (depending on various bonding mechanisms). The web needs therefore to be consolidated in one or the other way. The choice of the web consolidation method strongly depends on functional properties that are needed as well as on the type of fibres used..

There are three basic types of bonding:

- Thermal Bonding (cohesive bonding)

- Mechanical Bonding

- Chemical Bonding (adhesion bonding)

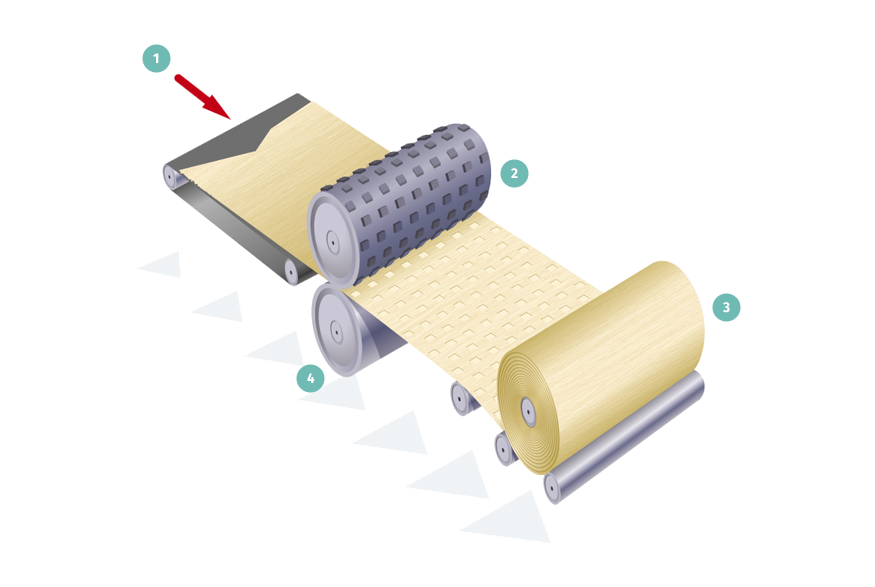

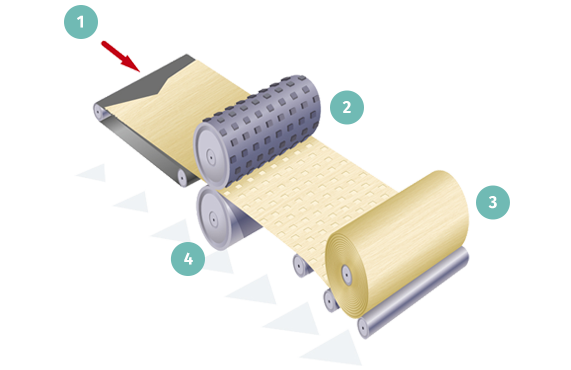

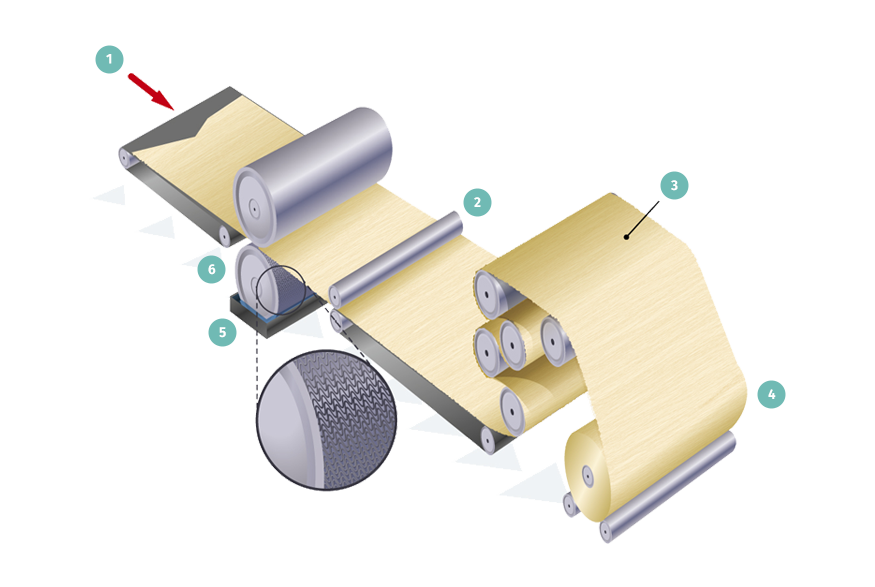

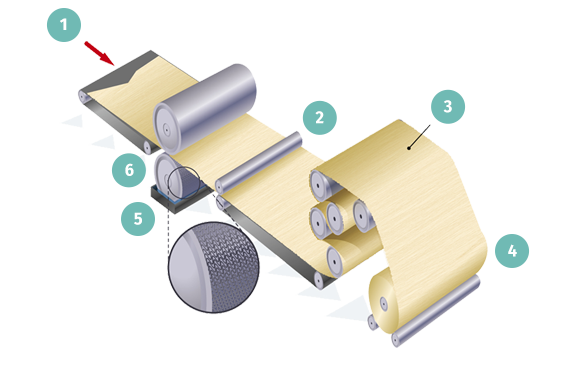

- From web forming

- Hot embossed cylinder

- Windup

- Hot smooth cylinder

There are several thermal bonding systems in use:

Calendering uses heat and high pressure applied through rollers to weld the fibre webs together at high speed.

Through-air thermal bonding makes bulkier products by the overall bonding of a web containing low melting fibres. This takes place in a carefully controlled hot air stream.

Drum and blanket systems apply pressure and heat to make products of average bulk.

Ultrasonic bonding is a technology in which molecules of the fibres are being ‘excited’ under a patterned roller by high frequency movement of a ‘sonotrode’ which produces internal heating and softening of the fibres.

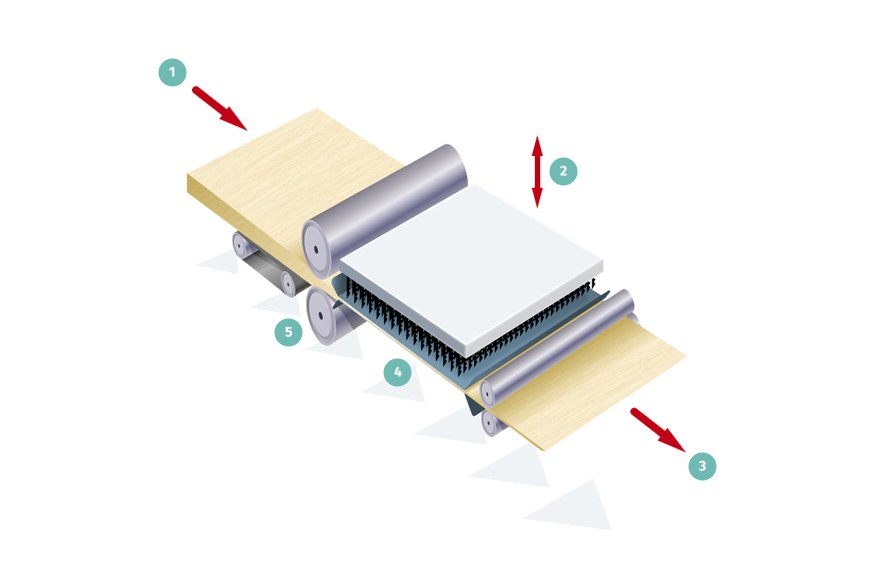

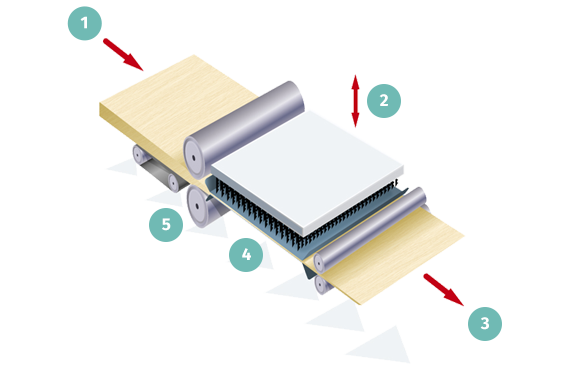

- From web forming

- Needle board

- To wind up or further bonding

- Needling

- Web compression

Needlepunching, specially designed needles are pushed and pulled through the web to entangle the fibres. Webs of different characteristics can be needled together to produce a gradation of properties difficult to achieve by other means. Needlepunching can be used with most fibre types but, because of the nature of the process, not with very fine fibers.

Hydroentanglement is commonly applied to carded or wetlaid webs and uses fine, high pressure water jets to cause the fibres to interlace. Hydroentangling is sometimes referred to as spunlacing, as the arrangement of jets can also be used to give a wide variety of aesthetically pleasing effects. The water jet pressure used has a direct bearing on the strength of the web.

- From web forming

- Nip rolls

- Drying

- Windup

- Pan with liquid binder

- Engraved drum (bottom)

The binder can be applied in many ways. It can be applied uniformly by impregnating, coating or spraying or intermittently, as in print bonding.

Finishing treatment

The opportunity to combine different raw materials and different technologies accounts for the diversity of the industry and its products.

This diversity is further enhanced by a range of finishing treatments. By finishing the nonwoven can be tailored or functionalized to meet specific properties. Finishing treatments can be either mechanical (stretching, perforating, crimping etc) or chemical. With the latter one can modify the surface of the fibres and the nonwoven to change the haptics or the repellency of the nonwoven.

Nonwovens can be made conductive, flame retardant, water repellent, porous, antistatic, breathable, absorbent and much more. They can also be coated, printed, flocked, dyed or laminated to other materials.

Converting

Nonwoven manufacturing ends usually with large rolls of product. Converters convert -as the word says- this roll good into a consumer product.

Sometimes converting is done in 2 steps. Before manufacturing the finished product one might want to bring the rolled good one step closer to the final product by slitting, cutting, folding, sewing or heat sealing.