Why use nonwovens in construction?

With increasing oil prices, climate change, CO² regulations and building regulation codes on fire resistance, nonwovens are providing cost-effective and efficient solutions to building and construction challenges.

The different uses are:

- Insulation (thermal and noise)

- House wrap

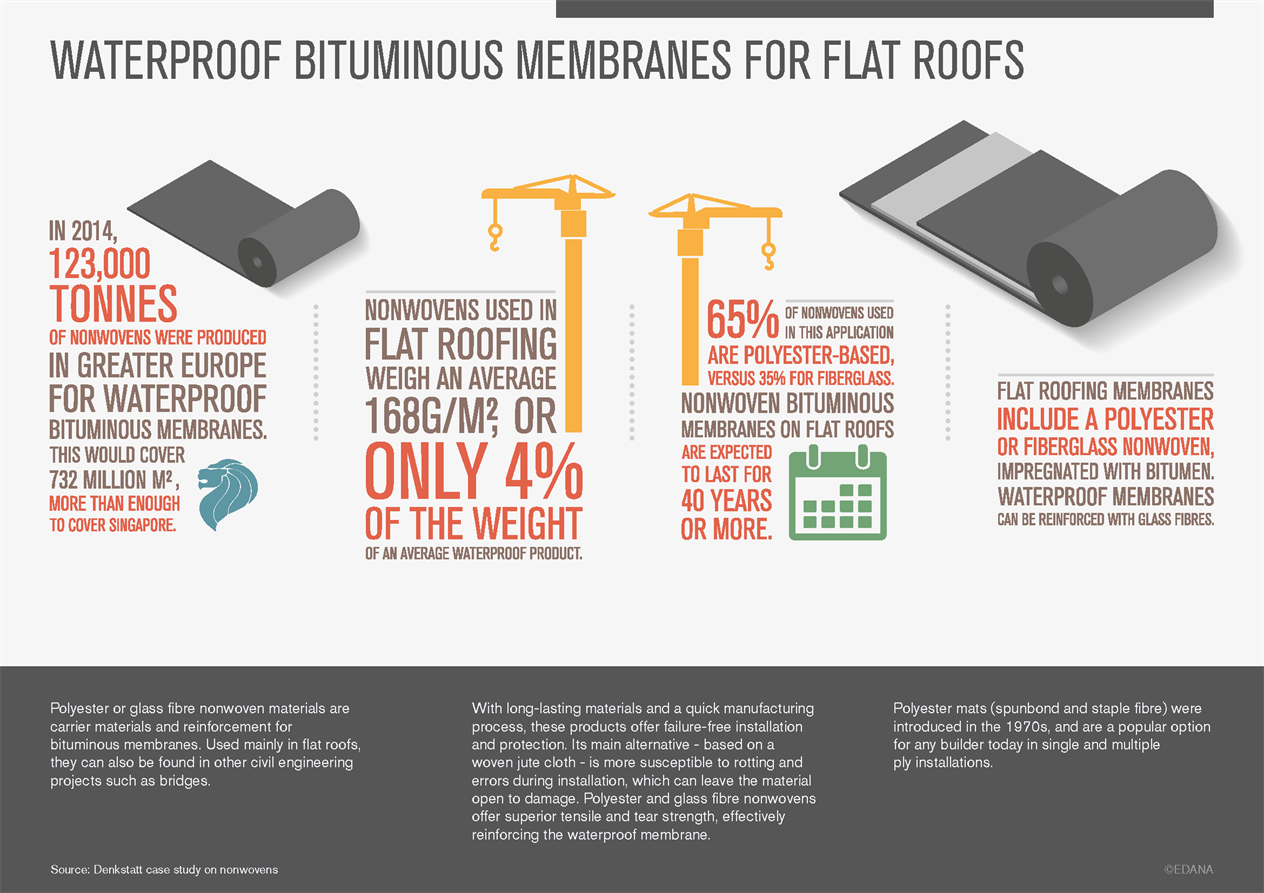

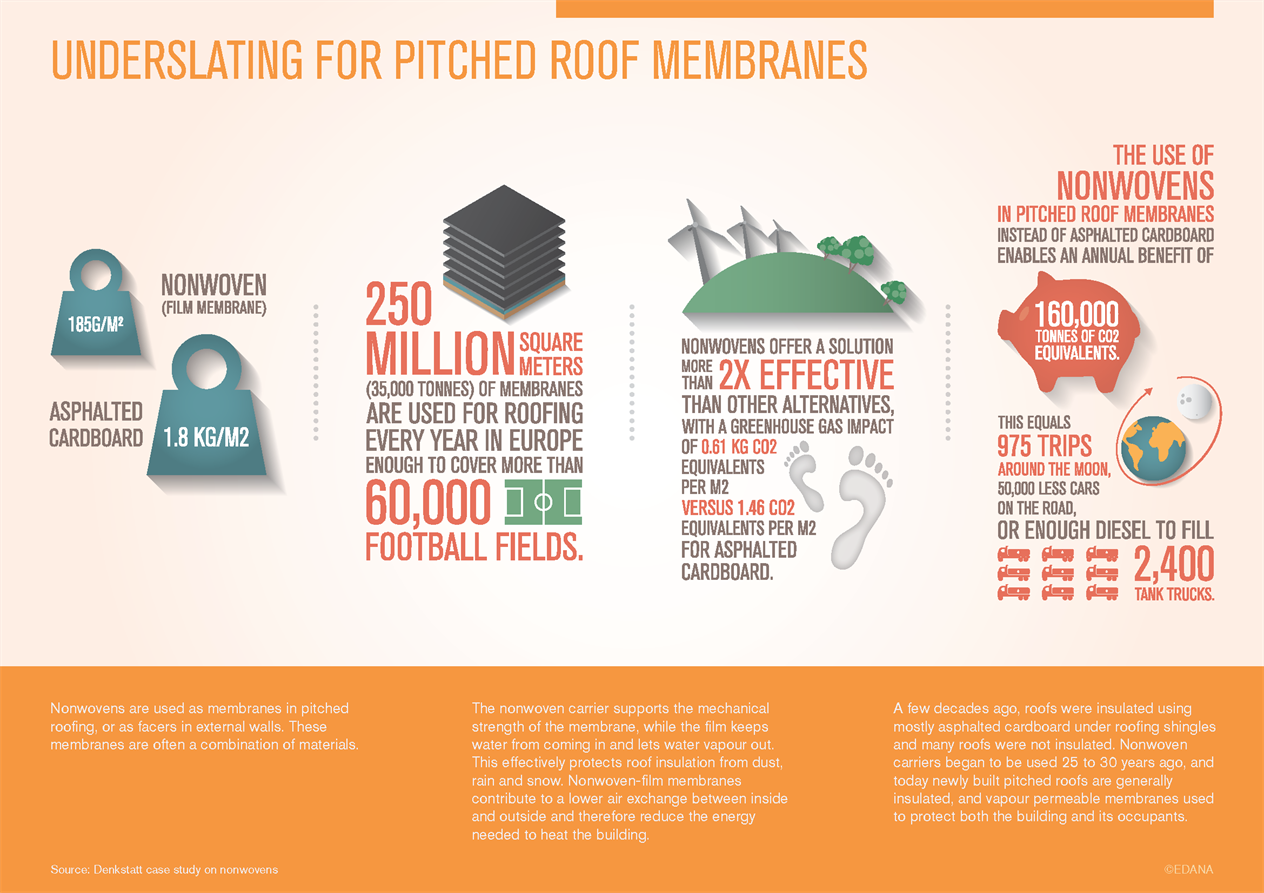

- Roofing

- Underlay

- Composites

- Membranes

- Underslating

- Covers for acoustic ceilings

- Air infiltration barrier

- Vapour barrier

- Flooring substrates

- Facings for plaster board

- Pipe wrap

- Concrete moulding layers

- Foundations and ground stabilisation

- Vertical drainage