Why use nonwovens in electrics and electronics?

The structure of nonwovens gives strength and elasticity. Nonwovens insulating tape can therefore stand the stress applied during the wrapping process as well as that which arises from varying degrees of cable dimension and flexibility in use.

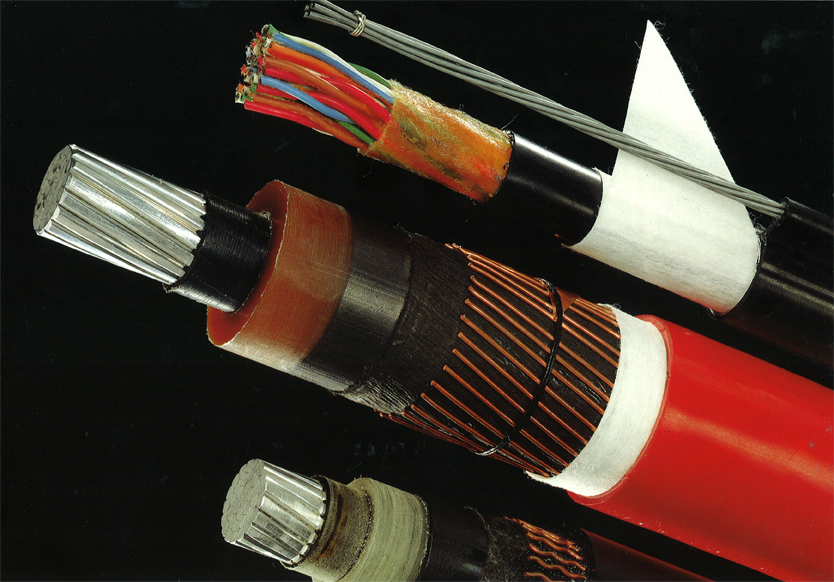

Different uses are:

- Power cables

- Communications cables

- Industrial cables

- Fuel cells

- Battery separators

- Cable wrapping