EDANA’s QAP: better standards, safer products

This article was originally published in the Sustainable Nonwovens Magazine (SNW), Issue April/May, 2025. Republished with permission. All rights reserved.

EDANA’s Quality and Audit Programme (QAP): How it was conceived and the impact it is having within hygiene product supply chains.

In early 2018, EDANA and its members came up with a simple and yet game changing idea to streamline the

industry’s auditing process: a voluntary standard that could harmonise audits efforts. Within the supply chains for hygiene products, many quality audits were conducted on an ongoing basis.

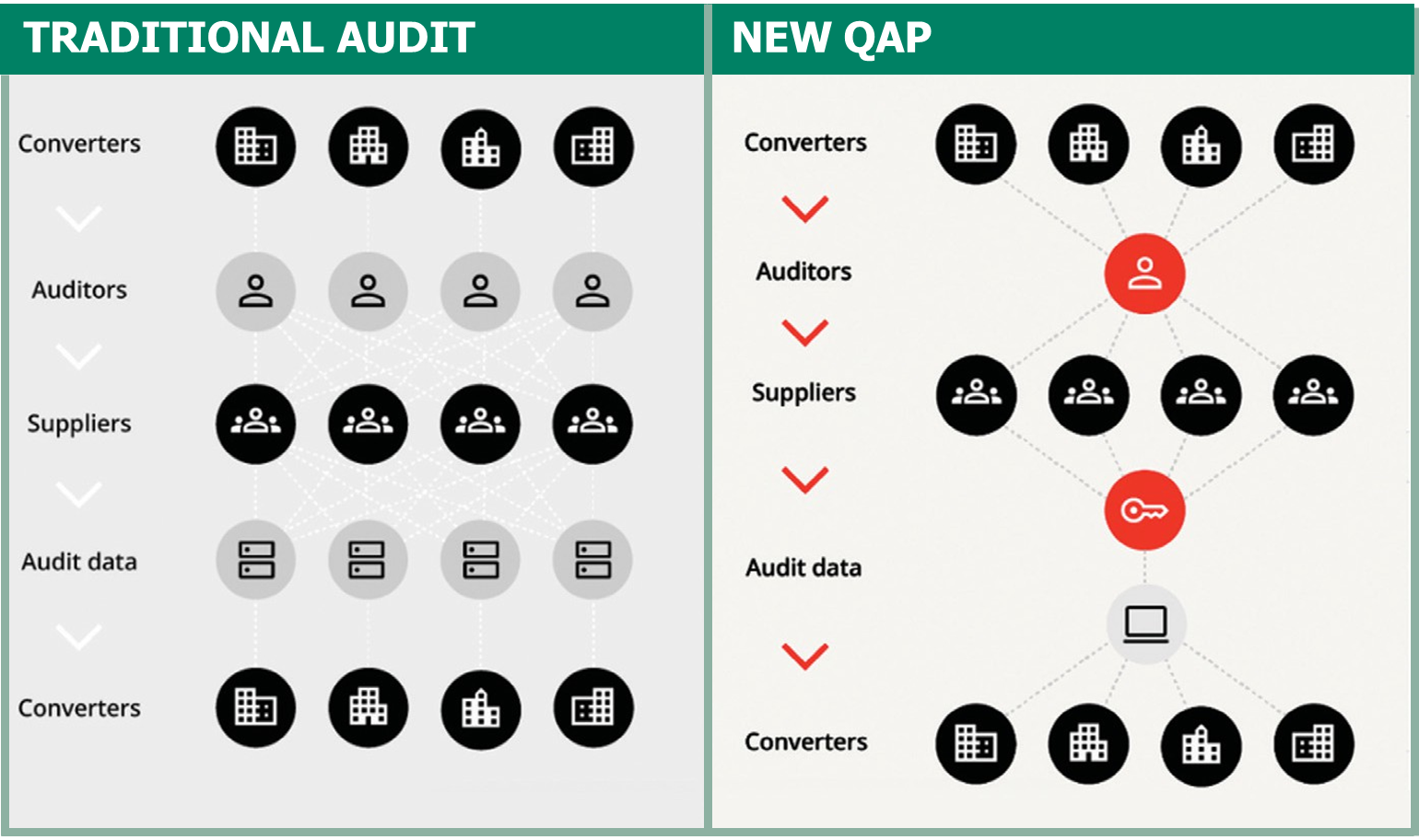

As there were multiple quality standards in use, audits performed by converters often resulted in duplicated efforts for a single supplier. Suppliers underwent multiple audits based on standards which were essentially similar and only differing in the details. That is where the Quality and Audit Programme (QAP) becomes valuable; it focuses on verifying and ensuring quality requirements. The initiative was inspired not only by the goal of harmonising audits but also by the opportunity to establish a consistent, industry-wide standard that could be applied uniformly across suppliers.

The QAP is a voluntary programme consisting of two parts. The first component establishes a fundamental quality benchmark, outlining the essential requirements for a supplier’s quality management system within the hygiene industry. This framework was developed collaboratively by EDANA and a diverse group of industry members.

The second component is a structured audit scheme designed to enhance efficiency and transparency in the industry. Audits are carried out by reputable, trained, and certified thirdparty auditors - currently in conjunction with the British Standards Institution (BSI) - ensuring consistency and reliability in the evaluation process. This approach eliminates the need for suppliers to undergo multiple, overlapping audits that assess similar criteria, reducing redundancy and operational disruptions.

Additionally, audit results remain under the control of individual suppliers, who can securely share them with selected converters through a cloud-based platform, cultivating greater collaboration and trust within the supply chain. By participating in the programme, suppliers show their commitment to quality in the hygiene industry. The audit report and the findings are reported in the cloud and is up to the supplier to give access to their customers.

In the hygiene industry, demonstrating consistent quality to stakeholders is chief. The EDANA QAP provides a clear solution. It establishes a harmonised benchmark, tailored to the sector’s specific needs, and ensures suppliers are rigorously assessed by qualified, independent auditors.

This provides external stakeholders with confidence in product quality, while internal teams benefit from a recognised standard that streamlines processes. Suppliers gain efficiency by adhering to a single, consistent audit, rather than navigating multiple bespoke requirements. Converters, in turn, benefit from a structured audit approach conducted by third-party experts.

The aim is to ensure consistent evaluation across the supply chain. Yet, continuous refinements to auditor training and standard implementation are ongoing to further improve alignment and effectiveness. Importantly, the QAP allows companies to maintain the flexibility to exceed EDANA’s established standards, encouraging continuous improvement. It is worth mentioning that there is no obligation for any company (whether supplier or converter) to join this initiative. It is offered as a tool for the industry, and the suppliers or converters may apply additional requirements to their quality systems.

Partnership

Since its launch in 2022, the programme has gradually expanded, incorporating key learnings to enhance auditor harmonisation, standard content, and global reach. Efforts are also being made to refine the number of available auditors to further strengthen consistency across evaluations.

To develop the QAP, EDANA needed a well-established leader in standardisation and auditing. A reputation in drafting standards precedes BSI, and so EDANA partnered with them to develop the quality standard. Their auditors, who undergo rigorous onboarding and continuous professional development, conduct the audits. BSI’s competency code system is designed to ensure auditors have the necessary expertise for specific industries, products, and specialised skills.

As the programme progresses, ongoing efforts focus on further harmonising auditor training and oversight to enhance consistency across different regions. In the future, the programme may open to other qualified auditing organisations that have the right capabilities. Furthermore, the programme includes a training for the auditees (the suppliers).

This is not a quality management course, but rather a focus on the ‘EDANA harmonised quality assurance standard’ for the hygiene industry. This course explores the key requirements and benefits of implementing the EDANA scheme, enabling suppliers to manage scheme conformity and drive continual improvement within their organisation. By achieving conformity with this internationally recognised standard, specifically designed for the absorbent hygiene products and personal care wipes industry, companies can attract and retain customers.

Suppliers and converters play crucial roles in the EDANA QAP, demonstrating their commitment to quality and meeting stringent customer requirements. As a supplier, they can showcase their dedication to quality by participating in the QAP, while as converters, you can partner with suppliers to ensure product quality.

To register, interested parties can simply submit a form through the EDANA website to connect with BSI, who expertly manages the audit schedule. BSI arranges audits with suppliers and notifies linked converters, enabling them to provide valuable insights.

BSI carefully manages access to audit reports and Non-Conformities (NCs), with suppliers having full access to their data and deciding which converters can access their reports. This ensures secure and controlled information flow. QAP audits are efficient and focused, lasting three days regardless of site size, emphasising system evaluation over physical scale.

Following each audit, the auditor provides a preliminary verbal report, followed by a formal written report on the BSI Connect Portal, including NCs, a rating sheet, and a summary statement. Transparency and confidentiality are prioritised, with audited suppliers owning their findings and selectively sharing them with chosen converters. Audit reports maintain confidentiality, omitting details that could reveal specific supplier -converter relationships.

In February 2024, the EDANA QAP Expert Panel and BSI revised the rating system to address discrepancies between the overall scores and the perceived outcome of the audit. The QAP has no minimum score to be achieved; however, the rating system provides valuable feedback. The new system, with a 0-100% rating, better reflects audit results. EDANA oversees the QAP through the QAP Expert Panel, ensuring smooth operation and deliverables (reports and corrective actions, that are relevant for the industry).

The road ahead

While the QAP has made significant progress, improvements are still needed, particularly in ensuring more consistent auditor evaluations, refining technical oversight, and expanding the programme’s reach.

As the programme continues evolving, potential future refinements may align with upcoming BSI commitments, such as finalising auditor coverage across key regions and appointing a technical leader for audit oversight.

Regulatory pressures have undoubtedly played a role in driving the development of quality standards across industries, but the EDANA QAP stands as a testament to the nonwovens industry’s initiative-taking and voluntary commitment to product safety and consumer trust.

This programme, developed in parallel with the EDANA Stewardship Programme for absorbent hygiene products, demonstrates a collective dedication to responsible product stewardship and continuous improvement. It is primarily designed for the AHP and wipes sectors, yet it offers potential applications for sub-suppliers and other areas within the hygiene industry. The QAP’s benefits extend beyond regulatory compliance, building confidence among stakeholders and consumers and driving advancements in product safety and efficiency. By harmonising standards and streamlining auditing processes, the QAP unlocks valuable efficiencies and promotes a collaborative approach to quality assurance.

Despite the significant progress, the journey towards achieving the QAP’s full potential continues. EDANA recognises the challenges ahead, including expanding the programme’s global reach, overcoming language barriers, and ensuring a sufficient pool of qualified auditors.

The commitment to the QAP remains steadfast, celebrating the achievements made while acknowledging the work that lies ahead. The QAP stands as a testament to the industry’s unwavering dedication to product stewardship, consumer safety, and the relentless pursuit of excellence.